- Top Results

- Bosch Building Technologies

- Security and Safety Knowledge

- Fire

- Frequently Asked Questions (FAQ) - AVIOTEC IP starlight 8000

Frequently Asked Questions (FAQ) - AVIOTEC IP starlight 8000

- Subscribe to RSS Feed

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

This article gives answers to frequently asked questions regarding the AVIOTEC IP Starlight 8000 Video-based fire detection.

1. Question

Can AVIOTEC replace fire detectors required by standards?

Answer

No, there is no product standard available for video fire detection.

Therefore, it is an additional technology, which is for example considered useful to comprehensive risk assessment.

AVIOTEC is used in areas/ applications, where standard fire detectors are not required by law/ standard or the necessary parties signed a special fire protection concept.

2. Question

Which cameras are available with video-based fire detection?

Answer

One box camera version is available: AVIOTEC IP starlight 8000.

3. Question

Can additional housings be used for the video-based fire detection AVIOTEC?

Answer

Yes, all protective housings that are used for the DINION IP starlight 8000 camera range (UHI-OG-0, UHI-OG S-0, UHO-POE10, UHO-HBG S-11, UHO-HBG S-51, UHO-HBG S-61) can be used -> Check the AVIOTEC page (accessories) at your regional product catalogue for details).

4. Question

What is the minimum distance from AVIOTEC to the fire source to detect a fire?

Answer

The minimum distance depends on the mounting height. The vertical mounting angle must be 37,5° or less.

For example: if AVIOTEC is installed at a height of 7m the minimum distance to the fire is 9,3m.

5. Question

What is the maximum distance from the camera to the fire source to detect a fire?

Answer

The maximum distance depends on the used lens, its opening angle and the mounting height.

For example: The maximum distance for a TF5 fire is 23m with a 90° lens opening angle. For an exact planning have a look at the planning tool. Find it at the product catalogue

6. Question

Which flame size can be detected with standard settings?

Answer

AVIOTEC detects flames with a size larger than 1,1% of the picture width with standard settings.

Therefore, the detectable flame size in 23m is 0,5m. To see detectable smoke/ flame sizes in the customers application use the planning tool!

7. Question

Is the detection of smoke independently from the smoke color?

Answer

AVIOTEC is able to detect grey and white smoke with an opacity of 40%.Black smoke is hard to detect due to missing structure and opacity (if the black smoke has the necessary opacity, it is a big open fire -> AVIOTEC will trigger the flame way earlier).

8. Question

Can AVIOTEC detect fires during fog, snowstorm, sandstorm or clouded lens?

Answer

No, the detection is based on an optical principle. If fires are covered by disturbance factors AVIOTEC can’t detect it.

9. Question

Is it possible to detect burning moving objects?

Answer

No, AVIOTEC detects fires, which are in a stable position in the picture.

10. Question

What is the minimum illumination level needed for AVIOTEC?

Answer

AVIOTEC needs a minimum illumination level of 2 Lux. If the illumination is less than 2 Lux IR illuminators can assist and let AVIOTEC detect also in 0 lux illuminated areas. For more details have a look at the newest FW version 7.72 manual.

11 Question

How can I measure the illumination of a scene?

Answer

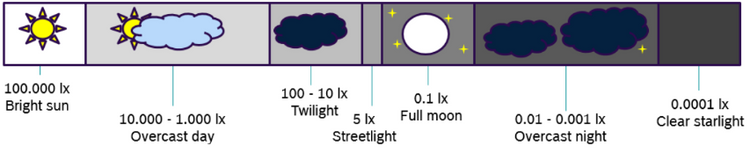

Lux meters can be used to measure the illumination. For a first guess tables exists with typical illumination levels:

12. Question

Does AVIOTEC detect flames and smoke?

Answer

Yes, it detects flames and moving smoke. The user can also decide only to use flame or smoke detection. The detection is an OR connection. That means that either smoke or flame must be in AVIOTEC’s viewing area.

13. Question

Where does AVIOTEC detect flames and smoke?

Answer

Flames and smoke can be detected within the full field of view of the camera.

14. Question

Which test fires are tested?

Answer

AVIOTEC can detect all test fires according to ISO/ EN standards:

- Open cellulosic (wood) fire (TF1)

- Smoldering (pyrolysis) wood fire (TF2)

- Glowing smoldering cotton fire (TF3)

- Flaming plastics (polyurethane) fire (TF4)

- Flaming liquid (n-heptane) fire (TF5)

- Liquid (methylated spirit) fire (TF6)

- Low temperature black smoke (decalin) liquid fire (TF8)

15. Question

Does AVIOTEC detect each kind of smoke?

Answer

The algorithm can detect up- and side-wards moving smoke up to an 180° opening angle. Ambient smoke with no movement and downwards rising smoke will not be detected.

16. Question

Can customers use alarm-based recording for root-cause analysis?

Answer

Yes, this feature can be used. Please make sure that the customer has agreed with the recording in the contract/ on an extra paper.

17. Question

Does AVIOTEC compete against standard fire detectors?

Answer

No, AVIOTEC is a supplementary system to existing fire detection technologies. On top of that: AVIOTEC can be used in applications where normal fire detectors are not installed due to ambient conditions (high ceilings, dusty /humid applications…)

18. Question

Is there a regulation?

Answer

Not at EN and ISO level. UL has an outline of the smoke detector standard and FM a test standard for video-based fire detection. Also, VdS now has developed an official guideline (VdS 3847).

19. Question

Why do standard fire detectors don’t work well in large halls/ high ceiling areas?

Answer

Standard fire detectors are mounted at the ceiling. Smoke from a fire source must reach the detector. The higher the ceiling,

the longer this process will take. Due to a longer detection time, fires can develop faster than being detected early by the AVIOTEC. In special cases inversion layers can exist in big halls (the reason behind are heat pockets beneath the ceiling). The smoke will not reach the ceiling -> standard fire detectors cannot trigger an alarm.

20. Question

Why not use a thermal camera?

Answer

Thermal cameras can detect heat. Smoke plumes from hidden smoldering fires cannot be detected.

21. Question

Regarding the AVIOTEC algorithm: is it camera- or server-based?

Answer

The AVIOTEC algorithm is an integrated solution inside AVIOTEC itself. The fire detection is independently from the connected server.

22. Question

Which systems can process AVIOTEC alarms?

Answer

Alarms can be transmitted via relay, metadata or ONVIF. Each system which can work with these data can be used.

23. Question

Which effort is needed to configure it in the applications?

Answer

In the camera itself, the fire and smoke detection is active with its standard settings as soon as the camera is installed,

powered up and the focus set. If needed/wanted the standard settings can be changed to special needs in the application (only two sliders and masking possibilities).

24. Question

Is AVIOTEC certified?

Answer

AVIOTEC has a VdS certification with a G number (G217090). It also has a certification from the CSIRO

25. Question

Where can I find more information about the product?

Answer

You can download operating and installation manuals, brochures, films and power point presentations from the Bosch product catalogue.

26. Question

How do I install/ position the camera, which angle?

Answer

Please check the operation guide of AVIOTEC for installation requirements. Also, plan the application of the customer within the planning tool for AVIOTEC.

27. Question

Can I use standard positions of existing video surveillance cameras for video-based fire detection?

Answer

Use the operation guide of AVIOTEC to check, if the position meets the requirements of AVIOTEC.

28. Question

Does the fire algorithm replace intelligent video analysis (VCA)?

Answer

No. Intelligent video analytics and video-based fire detection can be used in parallel but AVIOTEC must be planned an installed according to the operation guide. This is necessary to ensure the detection reliability for fire.

29. Question

Is the picture quality the same known from Bosch surveillance cameras?

Answer

No. Several adoptions at the picture were made to improve the fire detection functionality.

30. Question

How can I view the video?

Answer

Using standard browser (internet explorer) or video management systems.

31. Question

How do I see the alarm?

Answer

This depends on the used management system. You can also use the web interface of AVIOTEC. Use the operation guide of AVIOTEC for detailed information.

32. Question

Is AVIOTEC integrated in 3rd party video management systems (VMS)?

Answer

Via ONVIF and standard protocols (ETH connection) AVIOTEC is connectable to 3rd party VMS. AVIOTEC is fully integrated e.g. into the BVMS (Bosch VMS), Genetec, Seetec and Milestone systems (state 10/2018).

33. Question

Can I get alarms via ONVIF?

Answer

Yes, also ONVIF alarms will be transmitted.

34. Question

Is it possible to set the sensitivity?

In different applications, different false alarm rates might be acceptable.

Answer

Yes. You can choose different sensitivity settings according to the application needs (please check the operation guide regarding the exact settings).

35. Question

Is it one alarm that is triggered (OR connection)?

Answer

The alarms are triggered independently: one for smoke and one for flame. Either one of those has to be in the field of view of the camera to trigger a fire alarm.

36. Question

What do I connect to store and monitor?

Answer

Storage devices can be connected via network. AVIOTEC can be connected into the IP network.

37. Question

How do I connect AVIOTEC to my fire alarm panel?

Answer

We do not recommend connecting AVIOTEC directly (as a detector triggering external alarms) to a fire panel. Due to missing standards for VFD the direct connection to a fire alarm panel is only allowed as a local alarm; authorities will not be notified.

You can use the relay output of the camera for direct connection to the fire alarm panel. In special applications a dedicated fire alarm concept defined by every necessary party can change this. –> needs to be defined individually.

38. Question

What is POE and how does it work?

Answer

POE is an abbreviation for Power Over Ethernet. The Ethernet cable will be used for data transmission and empowering the devices. POE is standardized according to IEEE 802.3af-2003 or IEEE 802.3at-200 works with 48V.

39. Question

Does the camera use image databases to detect fires?

Answer

No. There are no pre-learned fire sequences used to detect fires. AVIOTEC uses physical behavior algorithms to detect fires in the scene.

The algorithm inside AVIOTEC is a mixture of physical behavior algorithms and an artificial intelligence. With the newest FW of AVIOTEC the benefits of this combination are measurable.

40. Question

Can we individually change the algorithm?

Answer

The algorithm can be adopted by sensitivity settings and verification time by using the web-interface. Also masking for flames/smoke can be inserted to adopt AVIOTEC to the applications needs. Please use the operation guide of AVIOTEC for get to know the details.

41. Question

Can the masking be set time dependently?

Answer

Since the FW release 7.61 it is possible to set three different profiles. Per profile, sensitivity settings, verification time and masking can be set separately. They can be set in a scheduler and adjusted to the applications needs (e.g. higher sensitivity during nighttime because no employees are around and fires need to be detected even earlier).

Also RCP commands can be used to switch between the profiles.

42. Question

How is the maintenance for AVIOTEC?

Answer

Please have a look at the new operation guide (since FW 6.50). The operation guide explains the proposed maintenance plans (according to the standards VDE gave for standard fire detectors).

43. Question

What to do in case of false alarms? How can they be prevented?

Answer

We have different setting possibilities to reject false alarms. Sensitivity slider and verification time can be adjusted. Also masking features and different installation positions from AVIOTEC can minimize false alarms. Please have a look at the operation guide where the influences and countermeasures are explained.

44. Question

Are there special mounting accessories for environments with vibrations from Bosch? How does this affect the camera?

Answer

Vibrations will affect the camera regarding false alarms. A vibrating camera can cause flame false alarms. To prevent those false alarms, choose another position to install AVIOTEC if it is possible in the area. If there is no possibility to install AVIOTEC without having vibrations there is the need to look for hardware, mounting the camera “vibration free”. From Bosch we do not have such a HW right now.

45. Question

How can I provide power supply backup to the camera? With which kind of certification power supply backup must comply?

Answer

Providing power to AVITOEC is possible via POE or/and 12V DC. If you provide both ways, there is going to be a redundant power supplied. Now AVIOTEC has a VdS certification and no EN/FM/UL. This means that there is no standard requiring power supply back up for AVIOTEC. If you connect AVIOTEC via the relay to the fire panel and include it into the fire concept, make sure to define the power supply backup there.

46. Question

What type of wire do I need to connect the camera (fire resistant?, Regular UTP?)?

Answer

Regarding cables we do not have any special request. Use the common fire cable for your region.

47. Question

In case of multiple fires in the area one AVIOTEC is monitoring: Are there any restrictions on the maximum number of fire focus can be detected and generate alarms with only one AVIOTEC?

Answer

AVIOTEC can trigger up to 256 different fire (smoke or flame) events in one field of view.

48. Question

Is it possible to monitor a trouble signal from the camera by the same relay that we monitor the alarm with?

Answer

Right now, this is not possible.

49. Question

As the relay only activates on alarm, how do you monitor troubles in the camera (power off, masking, etc)?

Answer

This can only be monitored by watching the video image of the camera-> or the camera is connected via Ethernet to a VMS, a shutdown/reboot (watchdog) from the camera would be detected by the VMS.

50. Question

If the flame is not fully visible, is AVIOTEC able to detect the flame?

Answer

AVIOTEC can detect a flame which has a size of 1,1% of the pixels from the field of view. The flame also needs to have a stable flame core and flickering to be detected by AVIOTEC. If the flame is half covered, it will need longer to be detected by AVIOTEC because it needs to develop longer. Nevertheless, as soon as the size is reached and the criteria are fitting, AVIOTEC will detect the flames.

Invisible flames cannot be detected -> no color, no flame core, only flickering which is hard to see also for the camera. AVIOTEC is an optical detection and not based on IR/UV.

51. Question

Which verticals are interesting because of the newest AVIOTEC FW version 7.72 with 0 lux possibility?

Answer

With the newest FW version applications get interesting where an invisible detection is necessary (without visible light). Also, applications where no redundant light can/ shall be installed – the IR illumination is less power consumption and ensures fire detection until the light is repaired.

52. Question

For day and night: Is there a separate configuration necessary?

Answer

No, the settings set for a profile are active day and night. If you want to have different settings for different modes: you can configure different time depending profiles

53. Question

Which IR illuminators can be used for the 0 lux applications?

Answer

IR illuminators having different wavelengths. For AVIOTEC 850nm as well as 940nm are working. Depending on the application itself, the respective range must be chosen. Make sure to test the illumination so that the whole field of view of AVIOTEC is illuminated.

54. Question

Is there a possibility to have automatic incident detection in tunnels at the same time with video fire detection?

Answer

Yes. With AVIOTEC 8 rules for AID can run in parallel to the fire detection.

55. Question

How to handle actual installations? Changing the mode to auto or leave it at color?

Answer

If IR illumination is already installed in this area the settings can be changed to automatic switch of color/ monochrome mode.

If no IR illumination is installed yet, leave the settings as they are: color

56. Question

How many masks can be set at the same time in one field of view?

Answer

In total 16 masks can be set for each profile and each field of view of one AVIOTEC

- For a better understanding of using Video-based fire detection AVIOTEC IP starlight 8000 and its features, we encourage you to join our online Camera fundamentals for AVIOTEC training from Bosch Building Technologies Academy!

Still looking for something?

- Top Results